Precision Custom Component Re-Creation

When Restoration Isn’t Enough: Manufacturing the Irreplaceable Part.

Your restoration shouldn’t be stopped by a piece of plastic or metal that simply does not exist anymore. At NOTZAuto, we go beyond repair and into manufacturing. We utilize advanced digital and physical fabrication techniques to faithfully re-create one-off parts that are truly impossible to find.

We provide the definitive solution for NLA components, ensuring your project moves forward with integrity and quality.

1. Capabilities That Solve the Impossible

Our expertise combines decades of automotive knowledge with modern manufacturing proficiency. We possess the tools and skill set to handle almost any challenge:

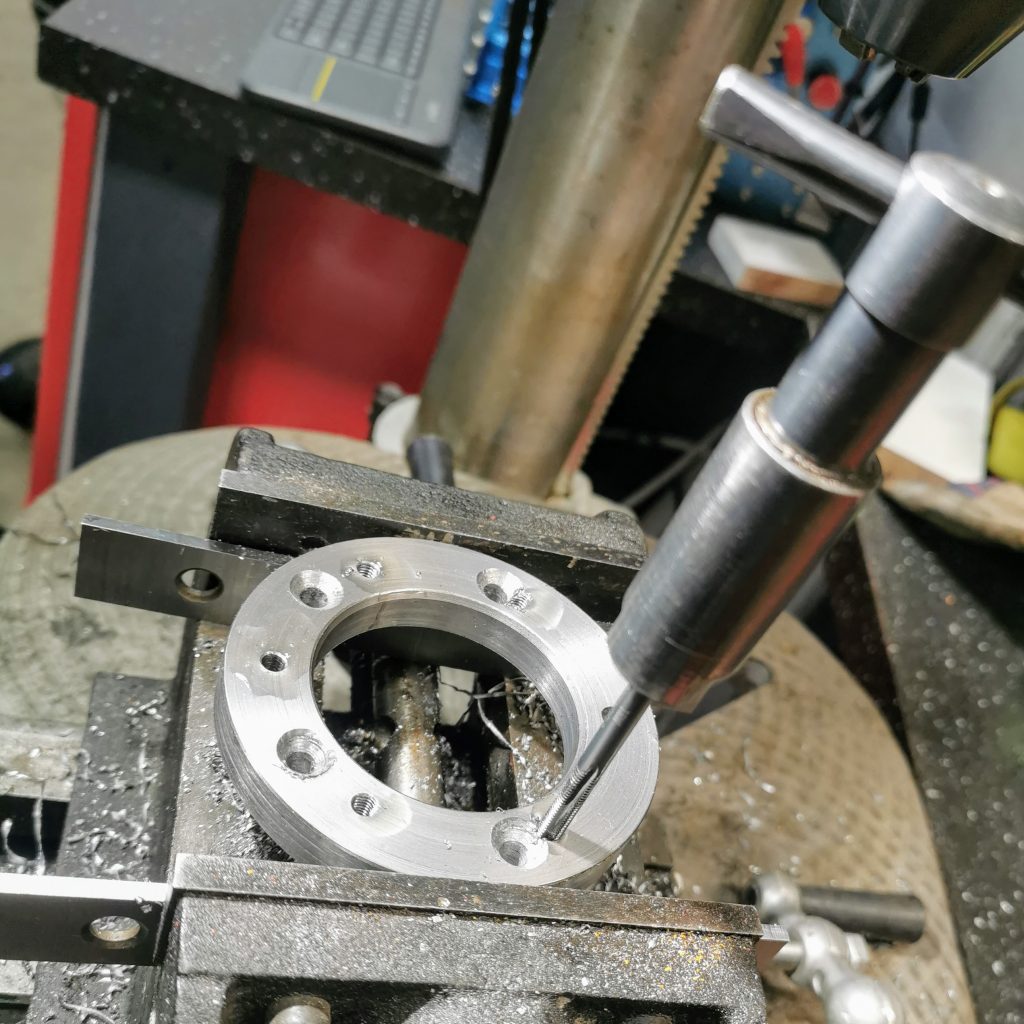

- CNC Machining: Precision milling and turning for metal components, ensuring perfect fitment and strength for structural or mechanical parts.

- Additive Manufacturing (3D Printing): High-resolution printing using materials that match or exceed the original properties, ideal for complex plastic housings, mounting brackets, and specialized internal components.

- Reverse Engineering: We analyze broken or remnant parts, creating precise digital models (CAD) to ensure the newly manufactured part is functionally and dimensionally identical to the original.

- Material Science: Selecting durable, modern plastics, resins, and metals that provide superior longevity compared to the aged original material.

2. Re-Creating Specific NLA Items

This service is ideal for components that are fragmented, totally degraded, or essential one-off parts with zero stock remaining globally:

- Proprietary Housings: Re-creating complex plastic or metallic enclosures for ECUs, relays, and sensors.

- Internal Mechanical Components: Manufacturing gears, levers, and specialized linkages within electromechanical assemblies.

- Trim and Fixtures: Custom production of unique interior or exterior plastic trim, caps, and hardware that impact the car’s aesthetic originality.

3. The Custom Re-Creation Process

Manufacturing a one-off part requires collaboration and precision. Here is how we guarantee success:

- Detailed Consultation: We review your original component (or fragments) and discuss the part’s function, material needs, and required specifications.

- Digital Modeling: We use CAD to create a precise digital model based on reverse engineering the original part.

- Client Approval: We confirm the digital specifications with you before any physical manufacturing begins.

- Precision Manufacturing: We utilize the appropriate technology (CNC, 3D printing, or a hybrid approach) to produce the component.

- Quality Verification: The part is verified against original specifications and prepared for immediate installation.

Ready to Manufacture the Part You Can’t Find?

If your restoration relies on an item that is truly unavailable, trust our engineering and manufacturing capabilities to deliver a solution.

Start Your Custom Project → Click here!